Trade names: Fluon, PTFE, Tarflen®, Boraflon, Reproflon®, Halon, Polyflon.

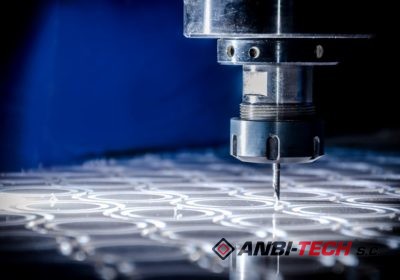

PTFE is available in the form of bars, plates, profiles, sleeves, tubes thick and thin, self-adhesive PTFE cambrics, grades and no glue, tape, cut and thread seals, foils.

PTFE is one of the most chemically resistant materials may be used in the temperature range -200 ° C to + 260 ° C. Timetables visible plastic is noticeable only at + 400 * C

The basic properties of PTFE:

- Excellent chemical resistance

- Very wide operating temperature range from -260 ° C – + 260 ° C

- Physiological neutrality – for food contact

- Very good sliding properties and abrasion

- Very good resistance to UV radiation

- Good electrical insulating properties

- Virtually no vibration phenomenon abrasive (ie. The effect of stick-slip)

- Nonincendive

PTFE application areas:

- Chemical Industry

- Electronics and Electrotechnical Industry

- Mechanical Engineering

- Construction

- Food

- Paper and Textile Industry

Examples of applications PTFE:

- Elements of equipment and fixtures

- All kinds of seals

- Connectors pipelines

- guards against aggressive pollution

- Isolators

- bearings and slip rings

- Valve Seats

- coatings for machine parts and equipment.

PTFE is approved for direct contact with food (EU guidelines and FDA) and is physiologically non-deleterious.

Offered by us blanks are approved.

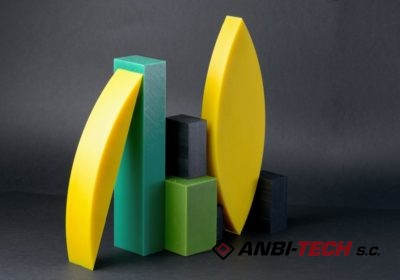

SPECIES

- PTFE delivered to our customers in the form of plates, rollers or sleeve is white. As the fluorinated polymer is obtained by polymerization of tetrafluoroethylene. In order to improve or modify the properties of PTFE enriched with fillers such as:

- PTFE + graphite reduces the friction thereby improving the mechanical strength and rigidity.

- PTFE + carbon allows for antistatic properties by which it is possible to replace PTFE which require a high temperature. It does not cause chemical changes Teflon.

- PTFE + bronze is to increase the hardness and the strength of PTFE compression and abrasion. High resistance to deformation, while a low coefficient of friction. Exhibits antistatic properties and good thermal conductivity.

- PTFE + glass fiber reduces the strain being the effect of loads, at the same time strengthens its resistance Teflon increasing friction